Mixed AC/DC off-grid photovoltaic power at "El sitgetí" organic farm (Catalonia, Spain)

El Sitgetí organic farm is located about 2 km away from the town of Bonastre

(Catalonia, Spain) in a little valley away from civilization! The farm

is located too far from the village to be connected to the electricity

grid. And although his owner, Charlie, has relied on a truck battery to

power his computer for the last 10 years it was about time to install a

decent size micro photovoltaic power plant there! The whole project

started by the acquisition of second hand solar panels (believed to be 3

years old, bought from a refurbished photovoltaic power plant,

80€/panel, a real bargain!). The system consists of 28 monocrystalline Silicon

panels of 220W power (Voc=48V; Isc=5.3A, FF=72%), for a total of over 6

KW (though this is a theoretical value, which is never matched in

practice)

|

| The 4 lines of 7 panels connected in series. |

So

I haven't talked all that long about DC power just for the sake of it!

Here is how we plan on taking full advantage of the DC power generated.

The 28 panels are connected as follows: 4 lines of 7 panels in series

are connected in parallel through 4 blocking diodes.

Each line produces a theoretical maximum power point voltage (VMPP) of

336V (at 1 SUN) which corresponds approximately to the maximum point of

the sine wave of the mains supply in European countries (230 x sqrt(2) =

325V) (see previous post for an explanation on that).

|

| Theoretical I-V curve of individual panels and of the 7 panel array |

The

DC source produced from the 4 lines of panels can therefore be used

directly to power equipment running on DC (battery chargers, variable

frequency drives, boiler, etc...). In practice the VMPP varies between

250 V and up to 400V (at 1 SUN), depending on various factors, such as

the external temperature, and the cloud conditions. We will refer to it

as DCV350, or DC BUS from now on. Despite this variation in VMPP our system will still

work perfectly as a DC source to power various equipment.

Map of the installation

| |||

| Map depicting the electrification of the farm |

The total land area

of the farm covers some 28 ha, which is pretty big. Luckily most it is

forest and only about 2 ha are actually farmed. Given the location of

the panels (placed at one of the highest accessible and most cleared

point on the farm) with respect to where the electricity is to be

distributed, some calculation were necessary to minimize voltage losses

across the wires. First the location of the ACV230 inverter was chosen

to be placed at middle distance between the most remote places where the AC

has to be distributed. This leaves about a 100m distance to be covered

by the current both ways before being consumed. Taking into account a

maximum power of 4000W (which is the maximum power of our inverter) this

leaves us with 10 mm2 wire diameter to limit the voltage drop to less

than 3% across the lines as is the norm in most European countries (click here

for a voltage drop calculator). For the DC lines, the cross section of

the wire can be downsized a bit because the voltage is higher that on the

AC line. The losses in this case will not interfere with appliances

operation as in AC in the case of a large voltage drop.

But it should still be minimized to avoid power generated being lost to

heat through the cables. A cross section of 6 mm2 was then used.

There are 7 points of connections and distribution, which are all marked on the scheme. Note that there is a set of battery in 4 locations. Battery sets of 12V are only used for illumination. All the light bulbs used in the farm are LEDs, so consumption is ridiculously low. All 12V sets are recycled batteries: one 20 years old NiCd , one > 30 old NiFe, two truck batteries, but they still offer a minimum autonomy of 15 days in our condition. The 24V set is a refurbished (9 years old) Lead/acid set, which has only a small fraction of its original capacity, but as explained in my previous post, the all point of the mixed DC/AC system is not to rely on batteries as in conventional systems.

All the batteries are charged via the DC BUS using switched mode power supplies (SMPS). The 24V set is charged with a modified welder/inverter (working on the same principle of SMPS) and is connected to the ACV 230 pure sine wave inverter.

All the batteries are charged via the DC BUS using switched mode power supplies (SMPS). The 24V set is charged with a modified welder/inverter (working on the same principle of SMPS) and is connected to the ACV 230 pure sine wave inverter.

Panels location survey, tilt angle and shading

Location

First of all it is imperative to know where the south lies respect to where we want to install our solar panels, there are different way to determine it, as explained here. Then the way we proceeded was to print the sun path chart for our location by simply entering the exact latitude and longitude of the site on this web site. We then built a solar elevation gauge by following the instruction of this very useful link. Given that the farm is located in a valley with hills on both sides, the hours of sunshine are slightly limited by the fact that the sun only goes over the east lying mountain about one hour after sunshine, and similarly for sunset. | |

| Solar path map. the green line at 11° elevation represent the hills located eastward and westward of the panels site |

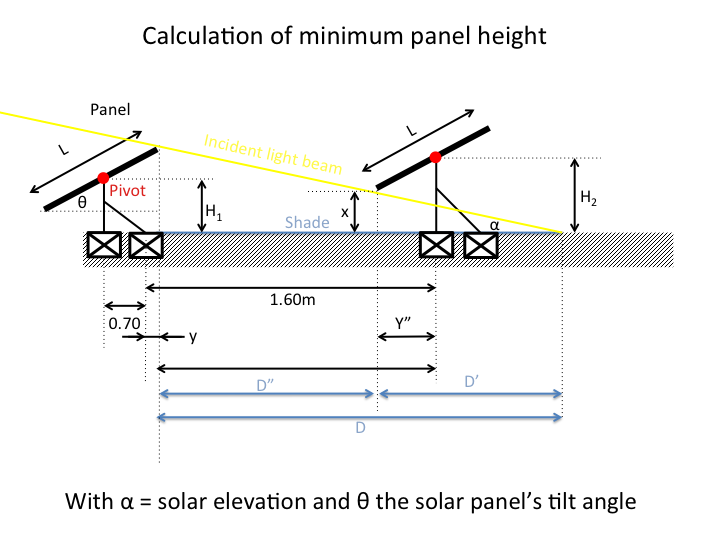

Tilt angle

Given

that we installed our panels on a flat surface it made sense to take

advantage of it to mount our panels on variable titling angle mounts. Unfortunately

given the height of the mount holding 3 lines of panels (see below to

understand why we chose such type of structure) it could only be

manufactured with 2 tilting options. Although the angles of maximum energy production

(for a 2 tilting angle system, with angle adjustment twice a year) are

16° and 54° in our latitude, we finally chose our system to be 17°

(summer) and 34° (autumn, winter, spring). This was, on the one hand, to

avoid the structure from being too tall and risking damage from strong

winds. On the other hand these 2 angular positions are optimum for

summer (17°) and spring-autumn (34°) which are the period of higher

activity and thus higher energy demand on the farm (low temperature

vegetable storage being the most import energetic demand in

summer-spring-autumn), winter being a very quiet season and sufficiently

cold not to require any additional energy to preserve vegetables. The

price of the two mount was about 1200 € (bought from Alusinsolar, Spain) .

No comments:

Post a Comment